- Project Overview

- Project proposals

- Project Craft

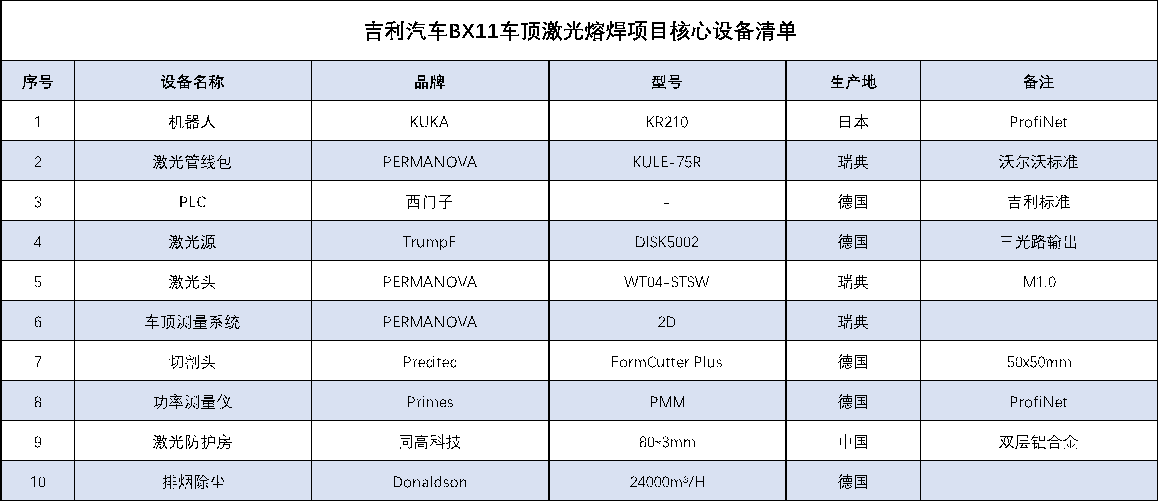

- Project equipment list

- Project site photos

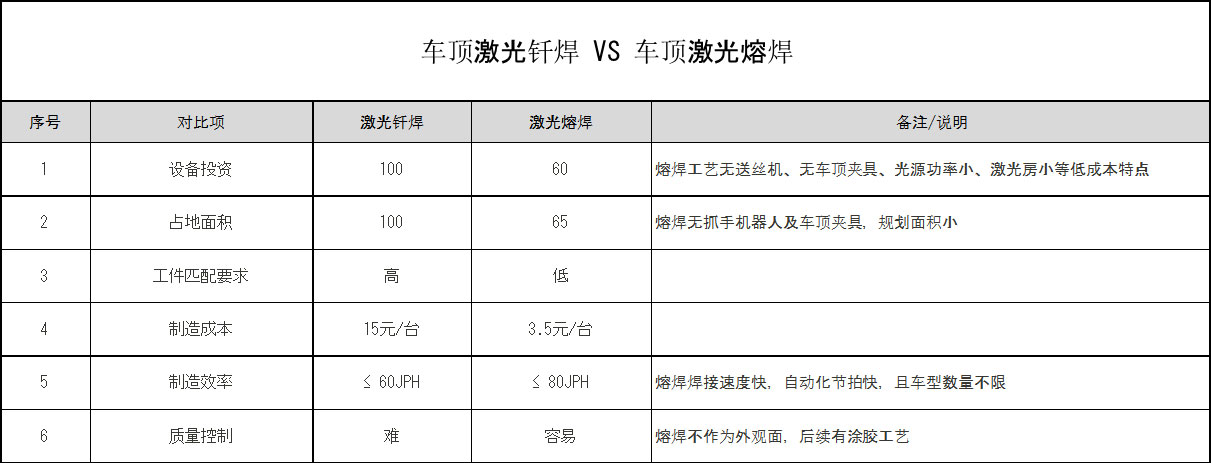

In April 2018, Tong Hi-tech undertook Geely Automobile’s new plant in Chengdu base, and was responsible for the “turnkey project” of the laser welding station for the top cover of the BX11 model. This is the same as Hi-Tech's fifth vehicle manufacturing base using roof laser welding technology after Geely Road and Bridge Base, Zhangjiakou Base, Hangzhou Bay Base and Yuyao Base. This process has absolute advantages over traditional laser brazing:

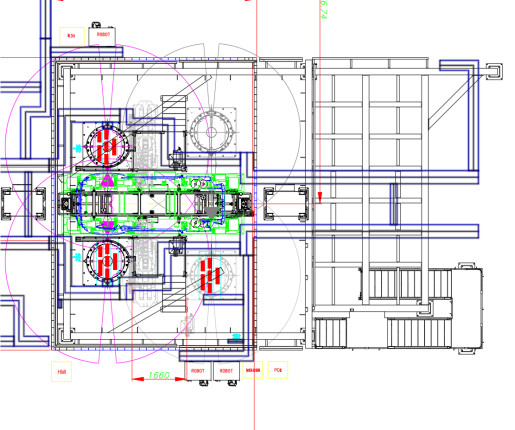

该项目坐落于吉利成都基地,车顶激光熔焊站位于白车身主线上,激光焊接房与激光源房设计为一体式两层结构,总占地面积为6x8x8米,一层为输送滚床、1台在线切割机器人及2台激光熔焊机器人,激光源房及除尘系统均摆放在二层钢平台上。

Ø 工位规划50JPH,节拍CT=61.5s,预留60JPH产能;

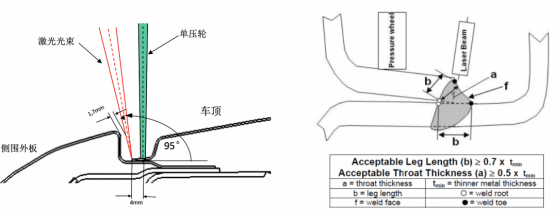

Ø 熔焊采用单压轮激光熔焊,替代车顶夹具功能;

Ø 高精度光学焊缝跟踪系统,可确保焊接质量的稳定性;

Ø 2D视觉车顶安装位置测量系统,测量节拍为10s;

Ø 熔焊焊接速度≥100mm/s,配合使用4kw激光器;

Ø 在线切割采用3D高精度图形切割头,切割范围为50*50mm;

Ø 单侧熔焊机器人可焊接左右车顶,作为焊接系统的降速互备方案;

Ø 激光熔焊系统采用世界先进主流工艺设备配置,可实现高品质焊接质量要求;

Ø 工位采用同高科技自主研发的双层铝合金的防护系统,并通过德国TUV安全检测及认证;

2D布局图

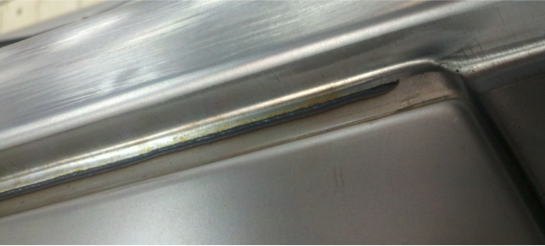

项目采用沃尔沃激光焊接工艺标准,选用PERMANOVA单压轮熔焊头,配合高精度光学伺服焊缝跟踪系统,并在焊接前根据2D车顶位置测量系统自动校正焊接轨迹,焊接焦点尺寸为0.6mm,焊接速度≥100mm/s。

焊接后的车顶焊接质量可以通过目视检查,或选配安装在线自动质量监测系统PLASMO。

English

English 中文

中文