- Project Overview

- Project proposals

- Project Craft

- Project equipment list

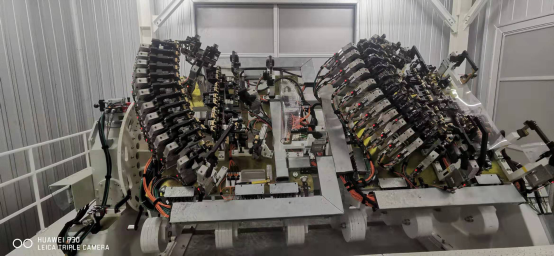

- Project site photos

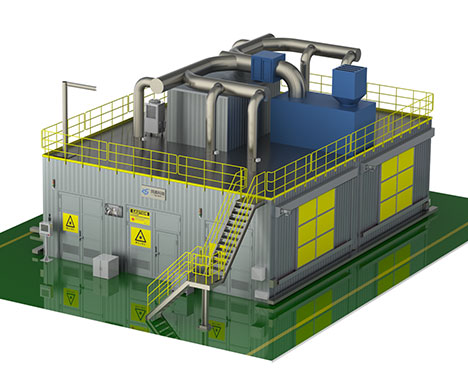

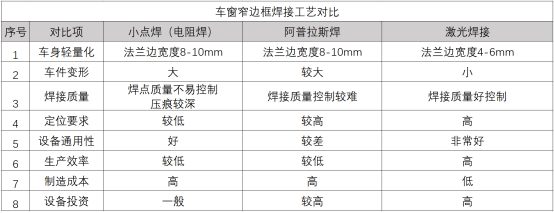

In January 2019, Tong Hi-Tech undertook the project of FAW Hongqi's welding plant at the Changchun base, and was responsible for the "turnkey project" of the four-door laser flight welding workstation for C229&E115 models. At present, in the process of body development, in order to enhance the visibility of the body, it is necessary to design the narrow frame of the window. This means that the width of the flange side of the window frame is narrow, and the traditional spot welding process cannot meet the manufacturing requirements. At present, there are three main manufacturing processes to solve the narrow frame of the body: small spot welding, Aplas welding and laser welding. Comparison of advantages and disadvantages of several processes:

该项目坐落于一汽红旗长春基地,激光焊接房与激光源房采用整体式设计,激光源房和除尘设备放置在二层钢平台上。左右前门(左右后门)共线生产,本项目采用激光飞行熔焊,车门材料为镀锌钢板,采用两序激光焊接。第一序为Dimple焊接,第二序为激光熔焊。两序激光焊接目的在于释放镀锌钢板在焊接过程产生的锌蒸汽,从而提高焊接质量。

Ø 工位规划20JPH,节拍CT=153s;

Ø 项目规划5车型,预留1车型。采用三面转毂转台进行车型切换,本期项目投产两款车型C229&E115;

Ø 车门内板和窗框均采用机器人上下件,自动化程度高;

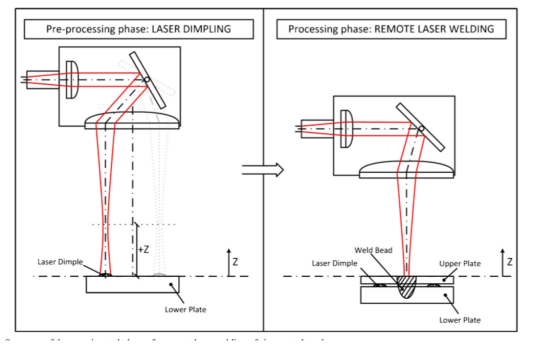

Ø 第一序Dimple焊接,保证两层板材之间控制0.2mm的间隙,释放锌蒸汽,提高焊接质量;

Ø 采用琴键式夹具,保证每条焊缝尺寸匹配一致性;

Ø 采用远程振镜焊接系统,提高焊接效率;

Ø 激光飞行焊系统采用世界先进主流工艺设备配置,可实现高品质焊接质量要求;

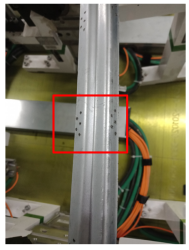

Ø 工位采用同高科技自主研发的双层铝合金的防护系统,并通过德国TUV安全检测及认证;

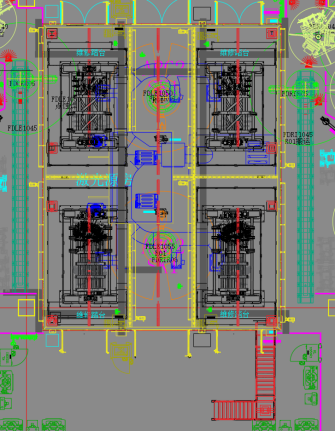

2D布局图

项目采用一汽红旗激光焊接工艺标准, 采用激光飞行焊工艺。焊接搭接形式为叠焊(Overlap,穿透焊接),作为镀锌钢板激光焊接,为了避免焊接过程中锌蒸汽对焊接质量的影响,采用2序激光焊接,第一序Dimple焊接,第二序激光深熔焊。

激光Dimple焊接 激光深熔焊

激光系统整体照片

四门飞行焊激光夹具

English

English 中文

中文