- Project Overview

- Project proposals

- Project Craft

- Project equipment list

- Project site photos

In July 2017, Tong Hi-Tech undertook the S111 capacity expansion project of Changan Automobile's base in Chongqing, and was responsible for the "turnkey project" of the laser brazing station for the S111 roof. Through the optimization of process equipment, the quality of laser welding of the body cover is greatly improved, and the qualification rate of body welding is improved.

根据客户需求,该项目采用单工位布局,2台激光焊接机器人及1台车顶抓手搬运机器人,车顶抓手搬运机器人安装在地面,规划2车型。方案设计可达到3车型+30JPH生产能力,实现了高柔性、高节拍、高质量的“三高”要求。

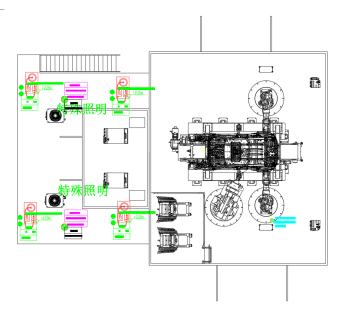

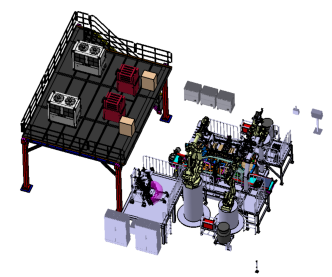

项目设计方案如下图所示:

2D布局图

3D效果图

项目详细信息如下:

Ø 单工位30JPH+3车型柔性生产,节拍CT=102s;

Ø 该工位目前规划3车型,可通过改造-在搬运机器人对侧新增一台机器人实现6车型规划,实现高柔性,高节拍,高质量生产要求;

Ø 改造后的产线,通过对工艺设备和焊接参数的优化,相比原有生产线提高了车身的焊接质量;

Ø 激光钎焊系统采用世界先进主流工艺设备配置,可实现高品质焊接质量要求;

Ø 工位采用同高科技自主研发的双层铝合金的防护系统,并通过德国TUV安全检测及认证;

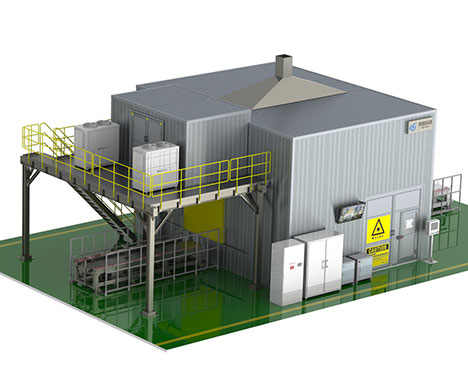

工位外部布局

工位内部布局

项目激光钎焊系统设备配置如下:

激光源房

English

English 中文

中文