- Project Overview

- Project proposals

- Project Craft

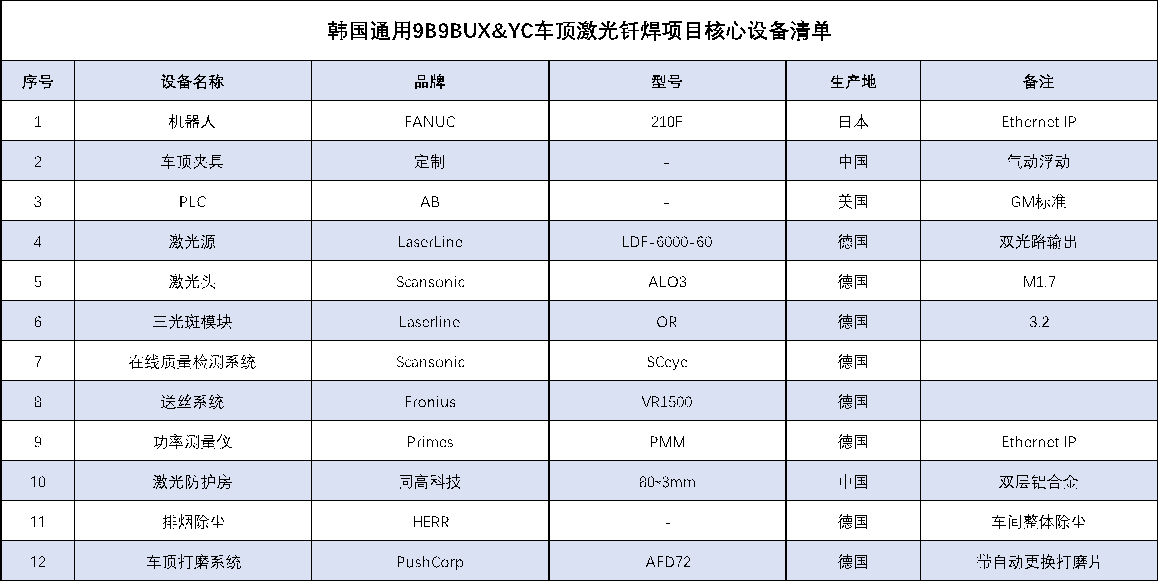

- Project equipment list

- Project site photos

In January 2017, Tung Hi-Tech undertook the “turnkey project” of the 9BUX&9BYC top cover laser brazing project of the GMK Incheon plant in South Korea. According to the customer's preliminary plan, according to the traditional roof laser brazing process (single spot, hot-dip galvanizing welding speed <3.0m/min), it is necessary to build a double station to meet the production needs of 4 models +60JPH. The same high-tech recommends the world's latest "diode three-spot" laser brazing process, hot-dip galvanized material welding speed ≥4.5m/min, automation efficiency increased by more than 50%, such a workstation can meet the production needs of 4 models +60JPH, In the end, this solution was approved by the customer and successfully implemented, which not only saved the budget of a workstation, but also greatly reduced the site area.

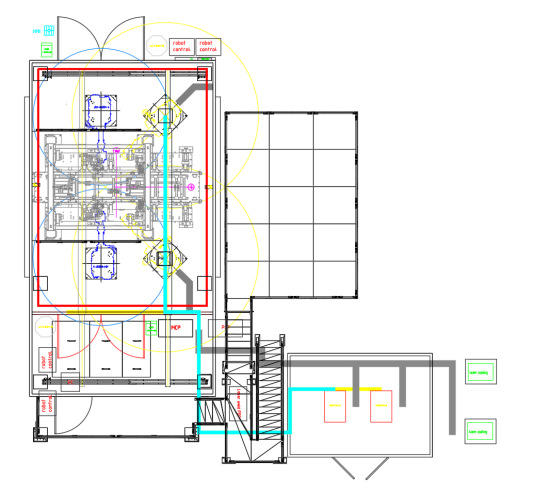

该项目利用原有生产线预留工位进行改造,新建的车顶激光站采用上下两层钢结构布局方式,占地面积6x12x8.5米,一层为输送滚床、龙门架及左右各1台激光钎焊机器人,二层钢平台上布局2台车顶抓搬运机器人及4套夹具库位,可实现混线无缝切换车型车顶夹具。

Ø 单工位60JPH+4车型柔性生产,节拍CT=52s;

Ø 该工位目前规划2+2车型,2台焊接机器人+2台夹具搬运机器人;

Ø 采用“三光斑”焊接工艺,实现高速、高品质激光钎焊焊接;

Ø 采用了在线质量监控系统,对焊缝表面质量实时自动检测;

Ø 工位采用同高科技自主研发的双层铝合金的防护系统,并通过德国TUV安全检测及认证;

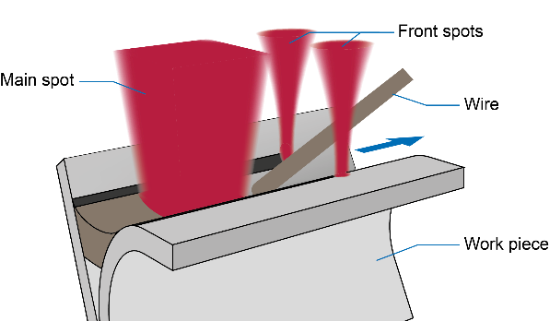

项目采用全世界最新“二极管三光斑”激光钎焊工艺,将LaserLine二极管激光器发射的一束激光束通过带有OR三光斑模块的激光镜组,分解为三个焦斑。

三光斑工艺图

其中焊接方向前的两个小光斑分布在焊丝左右侧,焊接过程中对车顶及侧围表面的镀锌层进行清洁,随后主光斑将焊丝融化并连接车顶和侧围板件,这样就解决了镀锌板焊接过程中锌蒸汽对焊接质量造成的焊接缺陷,从而最终能够有效提高焊接速度和焊接质量。

焊接后焊缝两侧的黑线特征

English

English 中文

中文