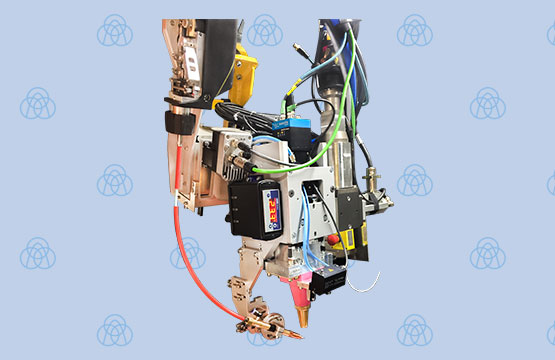

- product name:LSK 05-10

- category:thyssenkrupp

- Brand:thyssenkrupp

- manufacturer:thyssenkrupp

- use:激光焊接

- major client:

- description

- features

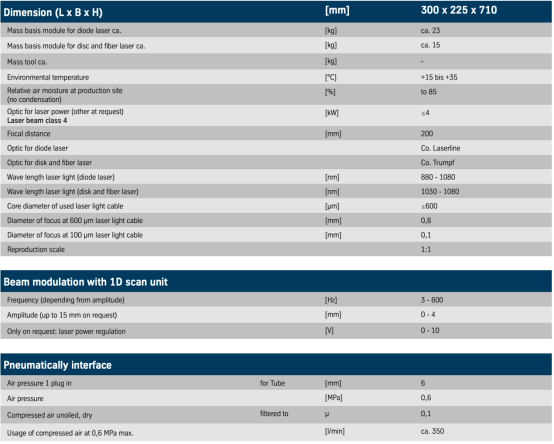

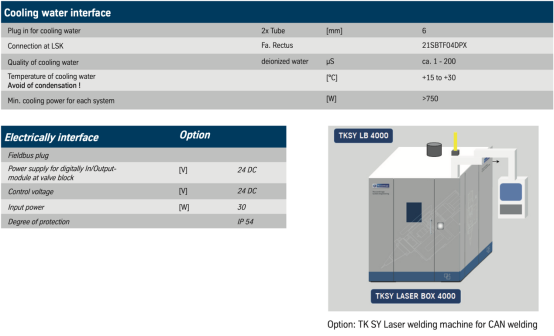

- parameter

- Case

One tool, many capabilities

How to achieve vehicle weight reduction? How to improve the body strength? How to optimize the passive safety of vehicles? ——Laser welding provides an effective solution.

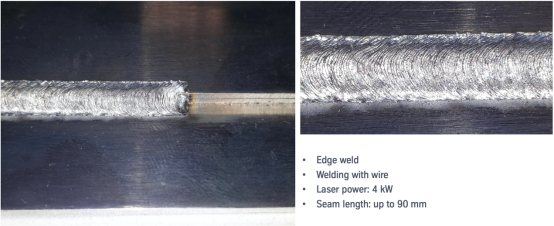

ThyssenKrupp has designed a compact and flexible body laser welding system-LSK05 series for well-known car companies such as German Volkswagen and Audi, which can not only meet the welding of aluminum alloy plates, but also meet the requirements of galvanized sheets and super Welding of strong steel body sheet metal.

LSK05-10 is a flexible and intelligent laser welding tool for aluminum alloy battery packs of electric vehicles with the most comprehensive functions so far. It combines all the features of products before LSK05 and incorporates innovative technologies to make it intelligent, efficient and stable. Laser processing tools have been successfully applied to the aluminum alloy battery production line of BMW, Mercedes-Benz and other first-class OEMs.

Ø 最大激光功率≤8kw(可定制最大20kw)

Ø 焊接速度快≤200mm/s

Ø 高精度Lessmuller光学焊缝跟踪系统,自带焊缝在线质量监测功能

Ø 高效的1D光学镜组,有效提高焊接强度,并适用于铝合金材料

Ø 特有的扫描填丝工艺,有效提高铝合金厚板焊接的强度及质量

Ø 采用螺旋喷嘴,有效延长护镜使用寿命及减少保护气使用量

Ø 聚焦镜下方安装有两块护镜,对聚焦镜双重保护

Ø 喷嘴上方设有便捷式护镜抽屉模块,并可实时监控护镜污染状态

Ø 采用总线通讯控制方式,可支持各种不同总线形式

Ø 可选配多种形式的夹指系统,夹紧力≤700N(可在线无级设定)

Ø 可全面提供设备的备件、维修、技术支持及培训等一站式售后服务

Ø 可为客户提供产品配置定制化服务

English

English 中文

中文