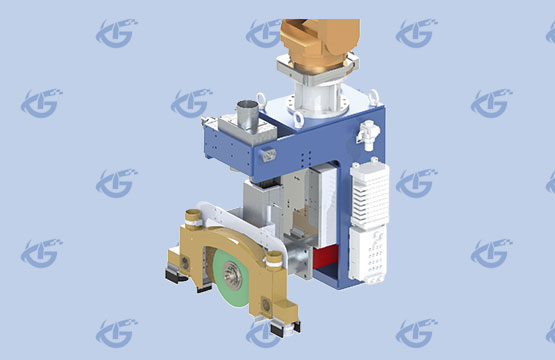

- product name:Polishing head

- category:Package product

- Brand:tg-amt

- manufacturer:tg-amt

- use:On-line polishing of the roof after laser brazing

- major client:

- description

- features

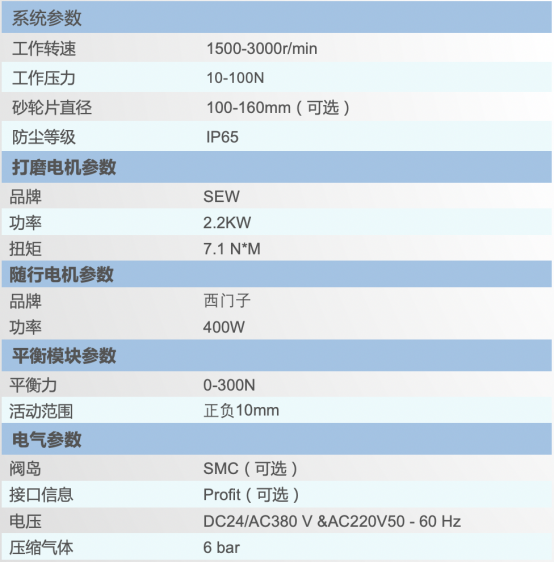

- parameter

- Case

The roof laser brazing process has been widely used in major domestic OEMs. With the combination of high technology and existing functional, efficiency and environmental protection application requirements, we have independently developed a new roof automatic grinding equipment IPS-1.0 (Intelligent Polishing System).

The IPS system is composed of five modules, including suspended grinding drive module, grinding disc automatic detection and replacement module, dust hood adaptive module, dust suction switch module and electrical control module.

The grinding equipment is suitable for the online grinding process after the laser brazing of the roof. The equipment adopts a modular design and is easy to install on site. Its function is to meet the single/double bilateral automatic suspension grinding, real-time detection of the wear of the grinding blade and automatic compensation for the cutting speed and The robot TCP trajectory effectively reduces the amount of grinding discs used, and can significantly improve the consistency of the grinding quality; at the same time, the distance between the dust cover and the roof is automatically adjusted, which can effectively absorb a large amount of dust generated during the grinding process to meet customer needs. Environmental protection requirements in the production workshop.

As the same high-tech patented product, IPS-1.0, with its high cost performance, high automation and high-quality environmental performance, will surely become the first choice of many customers for automatic polishing products.

Ø 气动伺服悬浮系统,自适应焊缝波动误差±10mm

Ø 打磨压力实时可控,压力精度±1N

Ø 特制的无极变速控制系统,可保持切削量不受打磨片损耗的影响

Ø 设备顶部法兰连接设计,可适用于车顶双侧打磨方案

Ø 独特的自适应除尘罩系统,可有效吸除打磨粉尘

Ø 标配高精度打磨片损耗在线检测装置,测量精度±0.2mm

Ø 可选配气动打磨片快换装置,有效提供加工站运行效率

Ø 可根据客户需求定制打磨片库位数量(标准库位为6个)

Ø 配套总线控制箱,内置PLC系统,可兼容外接不同控制设备

Ø 整机采用模块化设计,满足IP65标准,现场安装调试便捷

Ø 可全面提供设备的备件、维修、技术支持及培训等一站式售后服务

Previous:RMS cover measurement system

Next:None

English

English 中文

中文