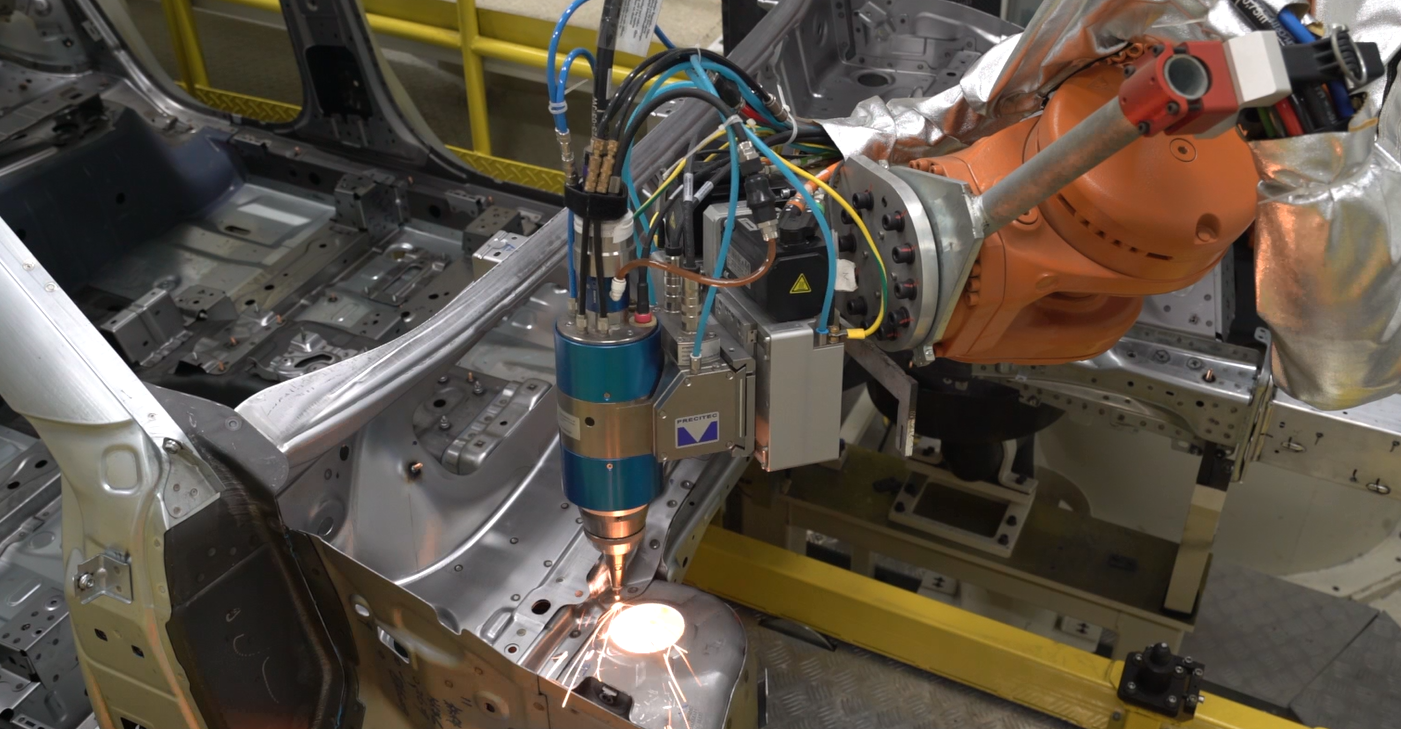

Laser welding quality judgment and laser head maintenance knowledge explanation

Release date:2020-04-08

In general, if we find that laser welding has problems during processing, first look for the cause of the material, check whether the equipment is not processed due to material problems, and replace it after checking the material, or you can change the setting of laser welding solve.

If it is found that during the welding of the workpiece, the problem of poor welding continues to occur in the same part, it may be the problem of the workbench and fixture, and the cause must be carefully investigated. When the situation of virtual welding or welding is found, we must check whether the laser welding energy is stable or whether there is a problem with the fixture table and the work table.

The laser head is the core equipment for laser welding. We must pay attention to the protection of the laser head, and must regularly clean and maintain it, and pay more attention in normal use to extend the life of the laser head.

Many people have neglected the maintenance of the laser head, so the laser welding efficiency has been greatly reduced, so how should the laser head be protected?

The first is cleaning. For the laser head, it must be cleaned regularly. Do not let some dirt affect the quality and effect of welding. However, if the laser head is not clean, then the laser energy will be affected when the laser is emitted. As a result, the laser will be accompanied by some impurities when it is emitted, which makes the propagation of light unstable and the quality becomes lower, which will affect the propagation of light.

Secondly, we must regularly check the use of the laser head. Once the laser head is found to be defective, it should be replaced and repaired in time to avoid affecting the production.

Finally, in fact, the protection of the laser head should start from the usual time. If you don’t pay much attention when using it, then the life of the laser head will naturally become lower.

English

English 中文

中文